The catalog contains special equipment produced by the PROMAVTO factory.

You can specify the price of a ready-made solution that is most suitable for your purposes.

Repair and welding unit on the K-701 "Kirovets" chassis

Description and equipment

Appointment of van: Repair and welding unit on the K-701 " Kirovets " chassis is intended for transportation and use of welding equipment by working crews in the places of repair work on the pipeline route at ambient temperature from -45 ° С to + 40 ° С.

Complectation:

C1-Базовая

Production time: on request

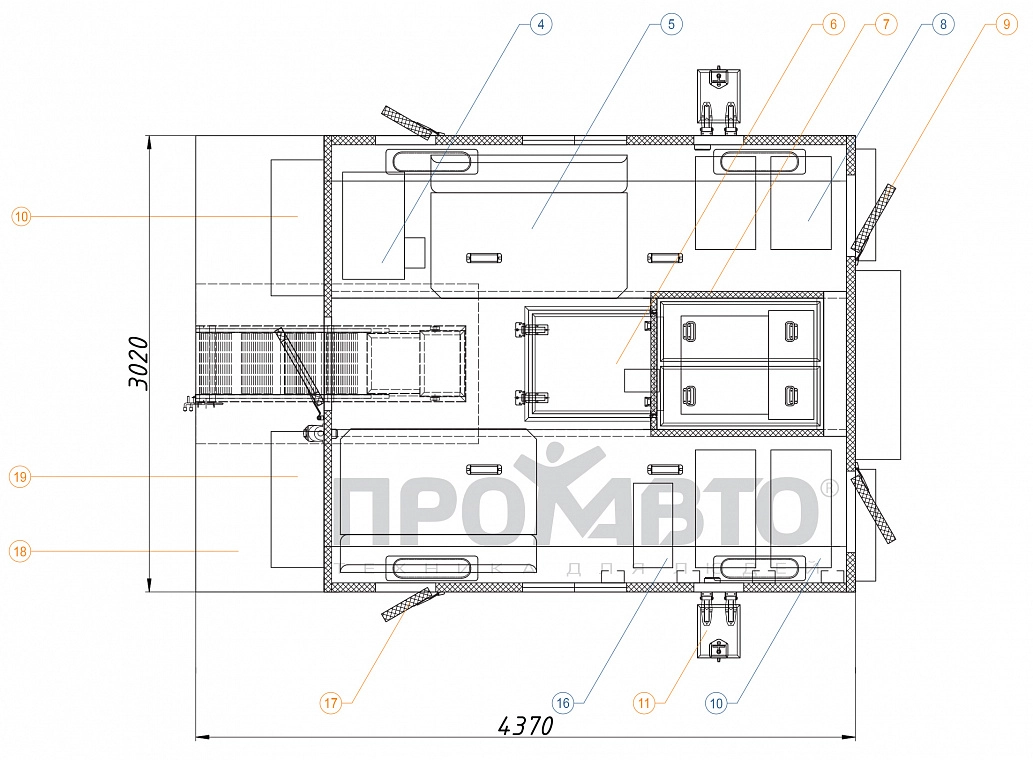

Internal equipment:

- Demagnetizing device.

Model: AURA (diameter of demagnetizable pipes: up to 1400 mm, range of demagnetizable fields:

2-250 MT)

- Welding machine.

Model: VD 506 (welding current regulation limits:

50-500 A, power consumption:

34 kVA)

- Welding machine.

Model: VD-306 (welding current regulation limits:

40-400 A, power consumption:

22 kVA)

- Electric furnace for calcining and drying welding electrodes.

Model: PSPE 50-400 (limit of temperature control setting: 50-400 ° С, one-time loading of electric furnace: 50 kg)

- Seat with backrest (upholstery material: brown leatherette, padding: foam rubber)

- Autonomous heater.

"Planar 8D" (fuel type: diesel, heating capacity: 7.5 kW, fuel consumption: 0.9 l / h)

External equipment

- Box for oxygen gas cylinders (4 pcs), made of steel with a yellow powder-coated polymer powder (RAL 1018)

- Tool box, made of steel

with yellow polymer powder coating

(RAL 1018), located under the van on the side (two on each side) - A roof rack constructed from the flooring of a metal profile pipe, fences, a handrail and a ladder on the rear door of the van, made of steel with a yellow polymer powder coating (RAL 1018)

- Hatch in the floor (opening direction - up)

- The partition for the generator inside the van, located near the front wall, with access to the generator from the inside of the van through the shutters opening up

- Hatch in the front wall (2 pcs)

- Hatch for 220 V sockets (on the left and right side)

- Hatch for cable entry (on the left and right side)

- A platform for cabinets for gas cylinders and fire extinguishers under the rear door of the van, made of corrugated steel with a yellow polymer powder coating (RAL 1018)

- Cabinet for a gas cylinder (propane) and placement of a sleeve for gas cutting, divided into two vertical compartments, made of steel with a yellow polymer powder coating (RAL 1018)

- Cabinet for a cylinder fire extinguisher, divided into two vertical compartments, made of steel with a yellow polymer powder coating (RAL 1018)

- Sunroof (opening direction - up)

Accessories

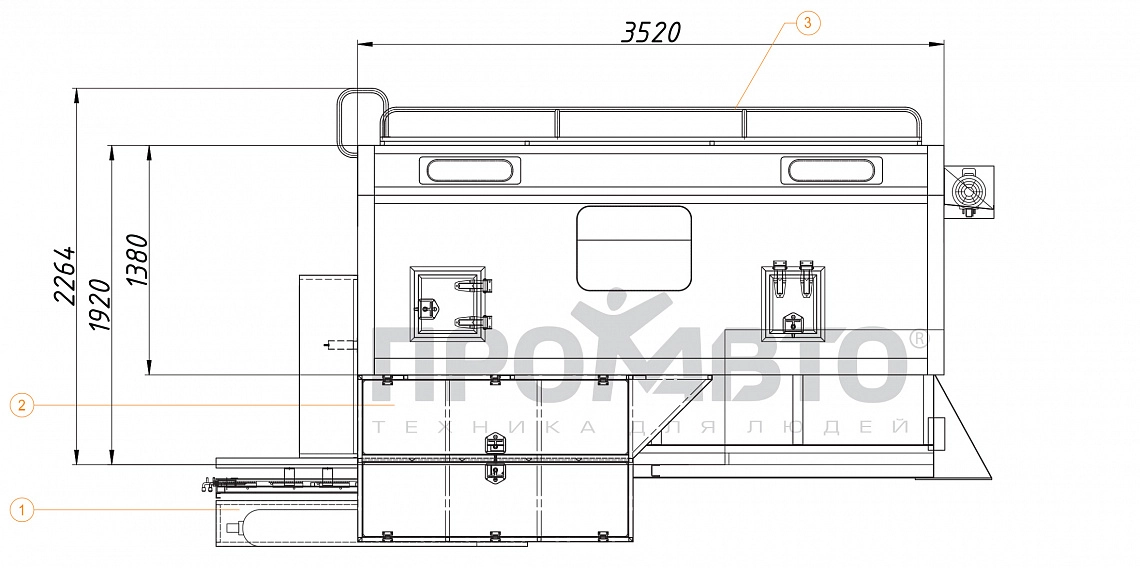

- Dimensions of the van (LxWxH): 3520х3020х2000 mm;

- The shape of the van – is kung (sloping upper corners);

- Color design: the van is painted yellow (RAL 1018) by powder coating;

- Internal lining: combined, interconnected sheets of galvanized steel with a polymer powder coating (top - gray (RAL 7035), bottom - brown (RAL 8012);

- The composition of the sandwich panel: lining, plywood 4 mm, insulation 50 mm, plywood 4 mm, inner lining;

- Internal framing: combined, galvanized corner with polymer powder coating (top - gray (RAL 7035), bottom - brown (RAL 8012);

- Side doors are missing; rear single-wing swing door with an opening angle of 180 ° and fixation in the open position;

- Cladding for doorway is made of steel profile with yellow polymer powder coating (RAL 1018);

- Windows in the van:

on the left side – hinged, with a size of 690x511 mm;

on the right side – folding, with a size of 690x511 mm;

in the bevels of the van – dead with a size of 500x140 mm

(2 on each side);

in the front wall – dead with a size of 404x564 mm;

in the back door there – dead with a size of 404x564 mm.

Our partners and clients